Mrp Erp

What Is The Difference Between Erp And Mrp Vienna Advantage

Mrp Vs Erp Which Solution Is Right For You Mrpeasy

What Is Mrp Ii Manufacturing Resource Planning

B E L Systems Limited

Difference Between Erp Vs Mrp When It Involves Manufacturing By Apagen Solutions Pvt Ltd Oct Medium

Heizer 14

Most MRP systems are software-based, but it is possible to conduct MRP by hand as well.

Mrp erp. Enterprise Resource Planning (ERP) is an application, or a set of integrated applications, that gives companies the ability to manage the “important parts” of the business. MRP can be connected to some systems, but the process is way more complex and not so common. Material Requirements Planning (MRP) ERP software for manufacturing and distribution From sales order to shipping and every step in between, OptiProERP’s Material Requirements Planning (MRP) software helps manufacturers operate more efficiently and more profitably.

However, Enterprise Resource Planning (ERP) and Material Requirements Planning (MRP) are two very different systems. Companies use material requirements-planning systems to. MRP is a software application that enables the manufacturing processes to plan, schedule, and control materials and their requirements.

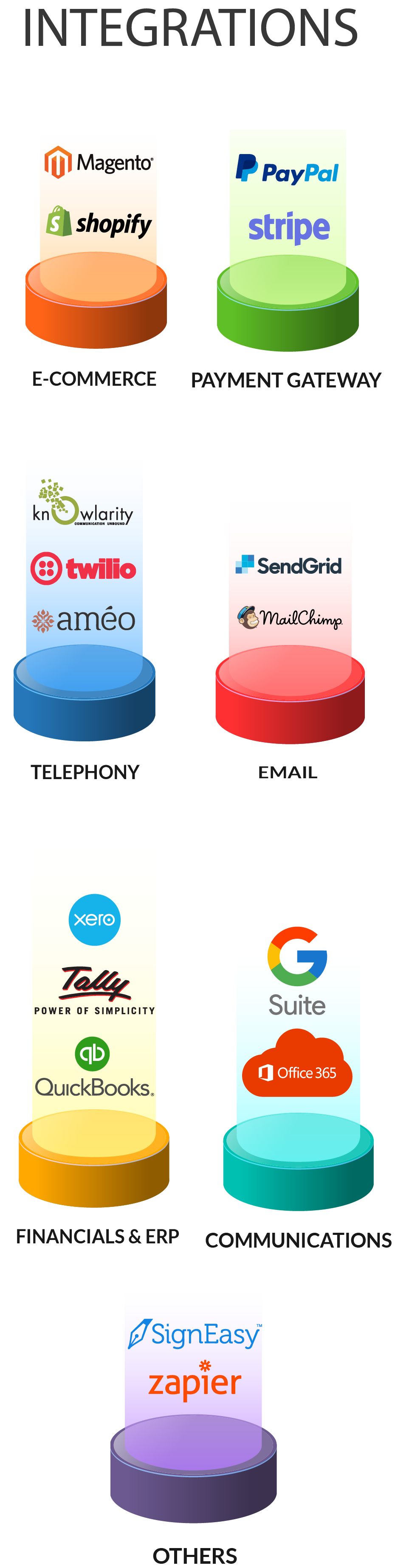

ERP software can be integrated into many other software suites to build a complete package of tools for optimizing your business operations in every possible way. It is an inventory control or management system. Simple, intuitive, and SME-specific, Statii helps SMBs stay competitive and grow by offering a wealth of tools for increasing productivity cost effectively.

MRP is more of a solo software. Most manufacturers use an organizational system called material requirements planning (MRP). 25th November 19 MRP, or manufacturing requirements planning, is a type of computer-based system developed to help manufacturers get the right material in the right quantity at the right time.

This means they are usually only utilized by the purchasing, production, and delivery departments. An MRP system is intended to simultaneously meet three objectives:. ERP at its core is an effective way of centralizing information and workflow processes through data management.

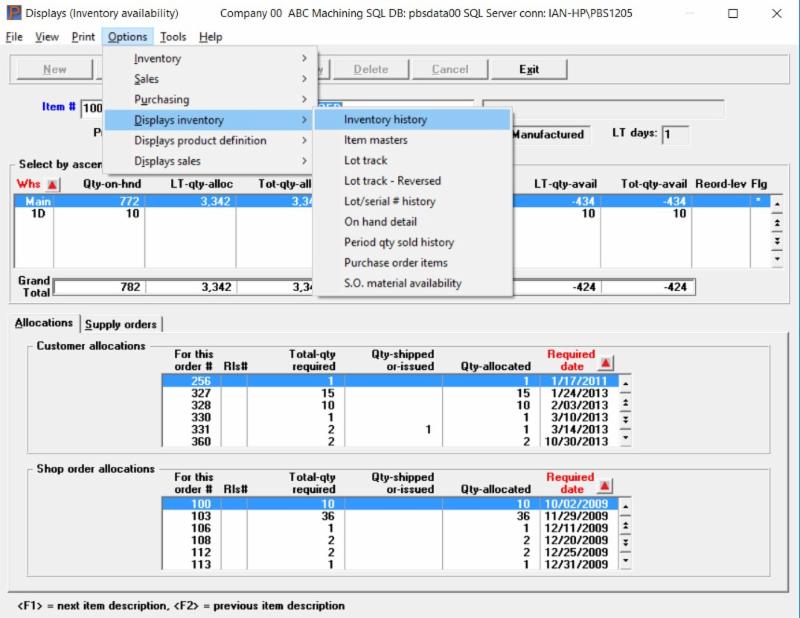

An ERP (Enterprise Resource Planning) system is the evolution of MRP II. Display worksheets, quality alerts to workers during operations. It allows you to easily schedule and forecast product demand, and creates a complete material plan which determines the quantities and delivery schedules of needed components.

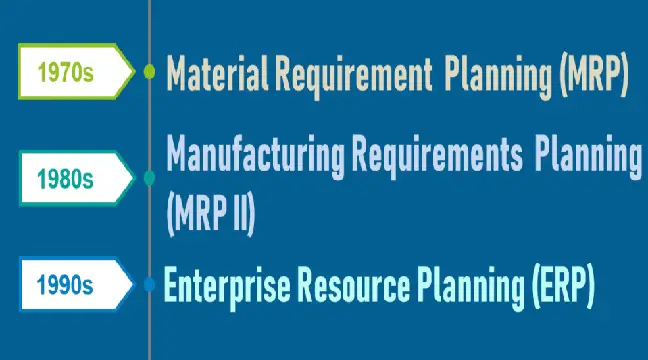

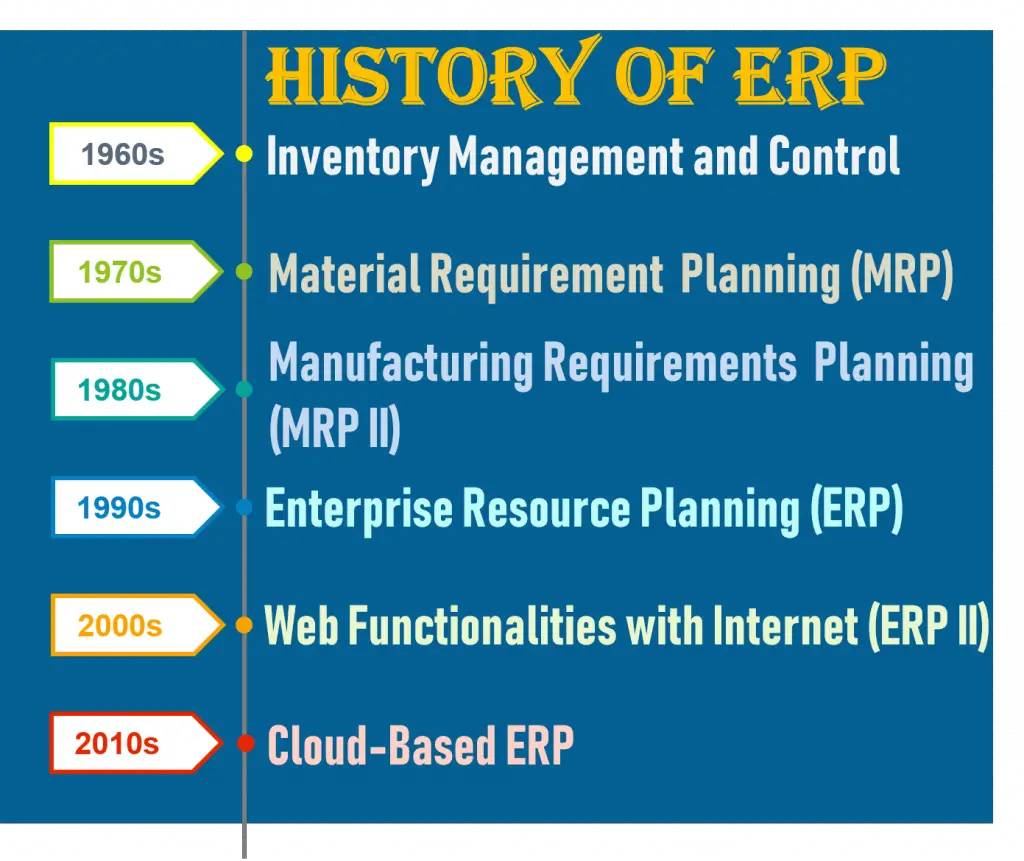

Work smarter and remove manufacturing process bottlenecks with the help of Statii software, an ERP and MRP software for small to medium sized manufacturing companies. MRP is a simpler solution than the complex ERP. The MRP system was developed in the 1970s and focused primarily on the inventory of production components.

First of all, it is important to know that MRP works as standalone software, while ERP is actually integrated. History of ERP and MRP systems. This data can be used for activities such as production planning, inventory planning, raw material purchase scheduling, and a range of other useful and important purposes.

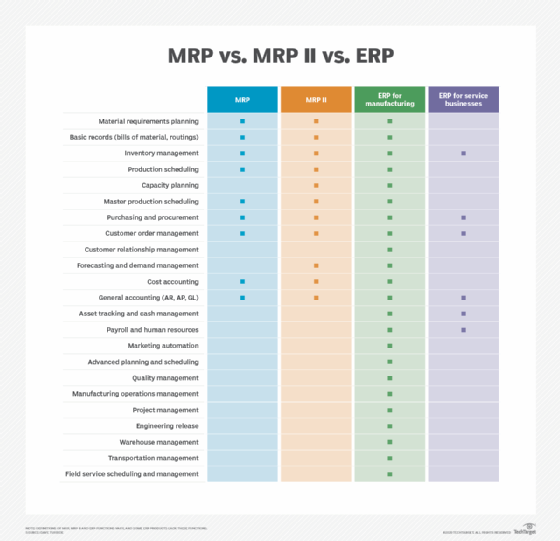

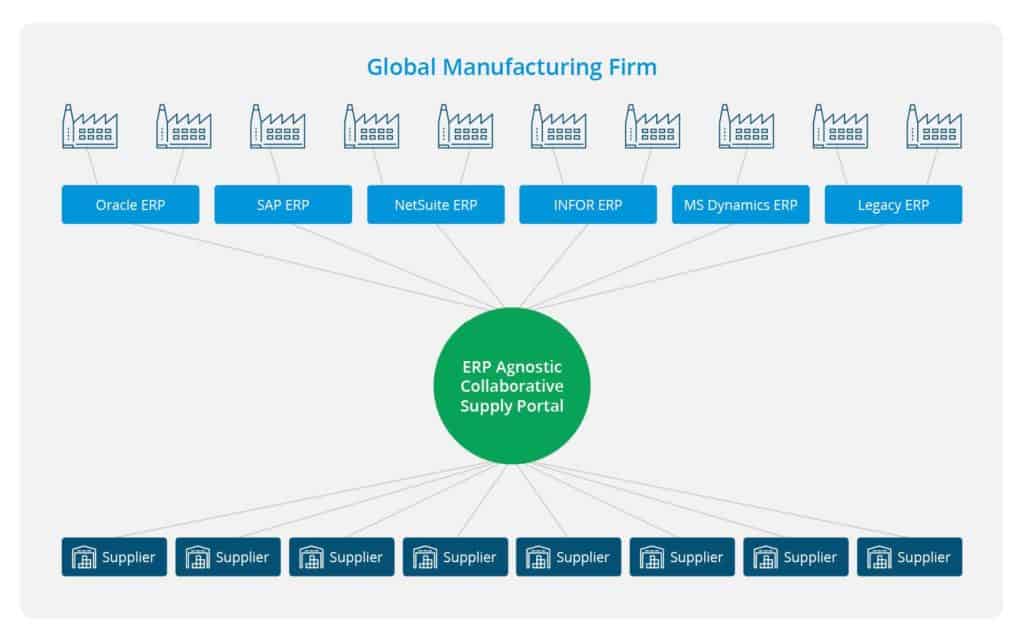

MRP (Material Requirements Planning) and MRP II (Manufacturing Resource Planning) are systems that control production and inventory. For manufacturers looking to streamline supply chain management, then an ERP system is the most sensible choice. Nearly every ERP system includes a basic planning module:.

An ERP is said to handle the company from end-to-end with areas like purchasing, accounting, human resources, sales, marketing, planning and more. MRP Systems and ERP Systems To make the best choice among existing platforms, it is best to first understand the difference between an MRP and an ERP. Capture data in real-time from your equipment using the API.

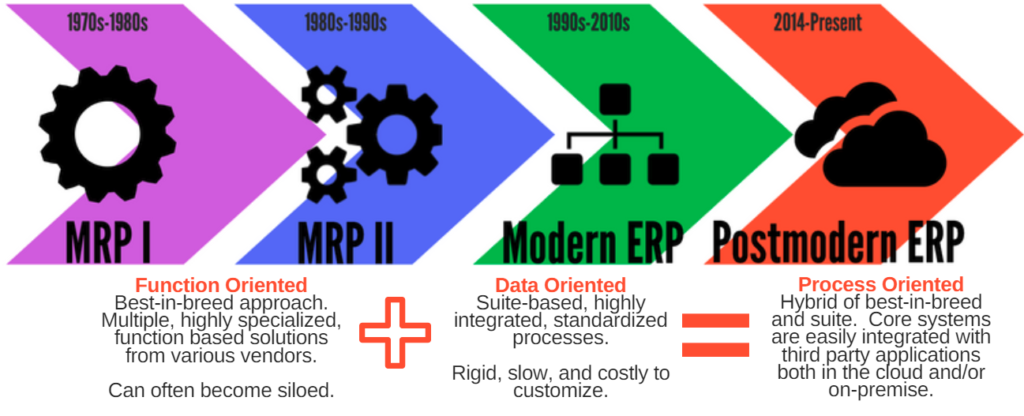

Even with these new abilities, MRP II is still pretty basic compared to what most manufacturers use now. An MRP system (or Manufacturing Resource Planning system) is used by manufacturers for the purpose of integrating business data within a single system. Featuring real-time demand planning, visibility across product life cycles, and strong integration with accounting software, NetSuite offers a powerful MRP in the form of its Demand Planning functionality.

ERP and MRP are acronyms for software technology that enables people to perform company processes. ERP has the ability to connect to other software modules and systems seamlessly, and it is a modular network. Difference Between MRP (ERP) or Kanban?.

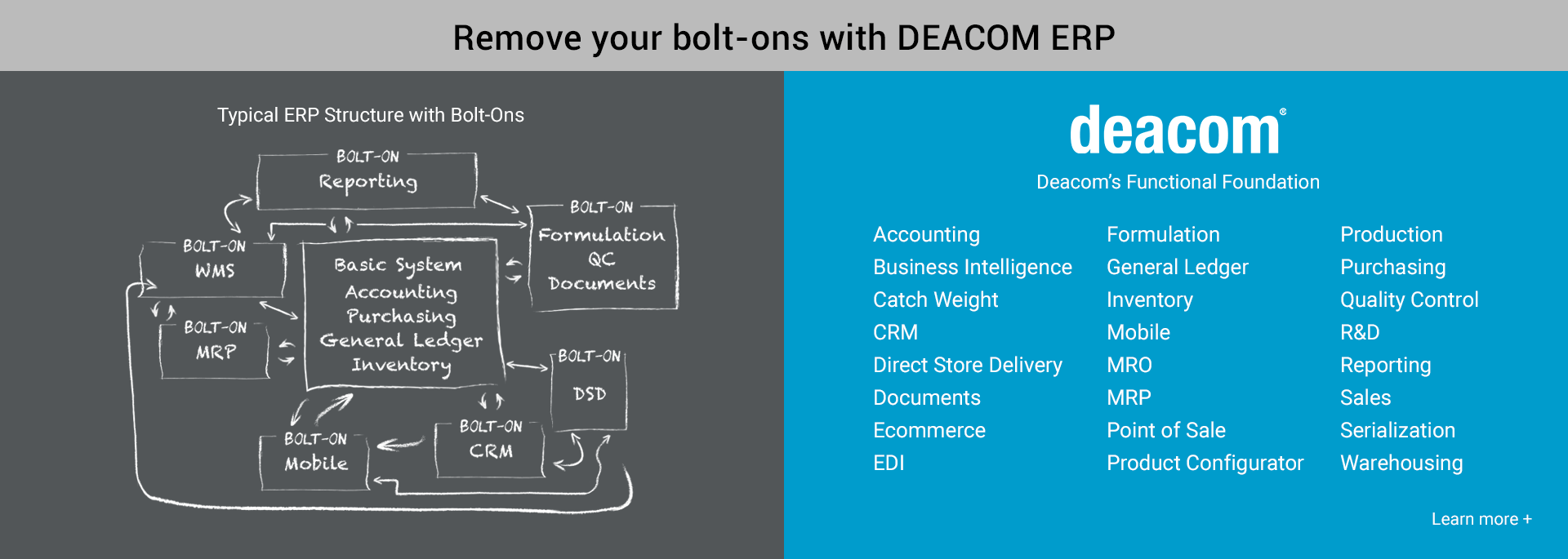

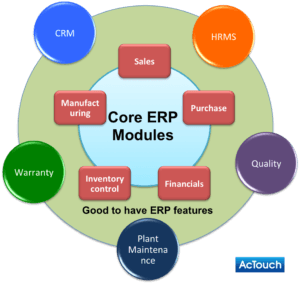

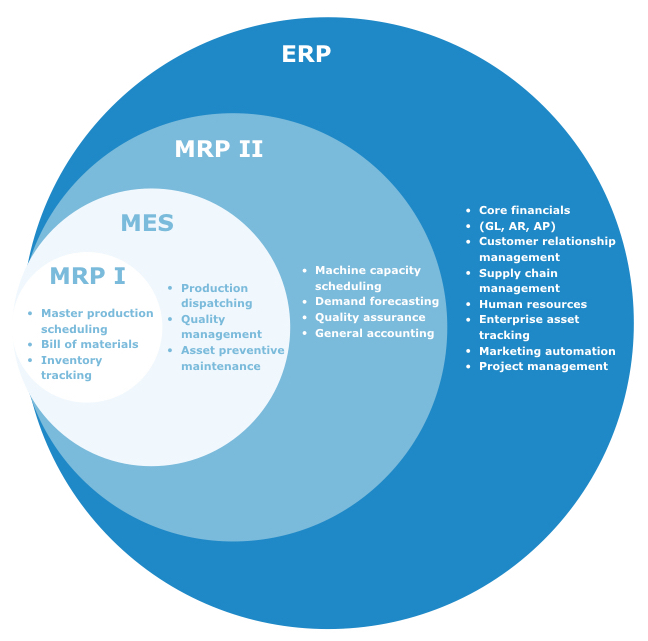

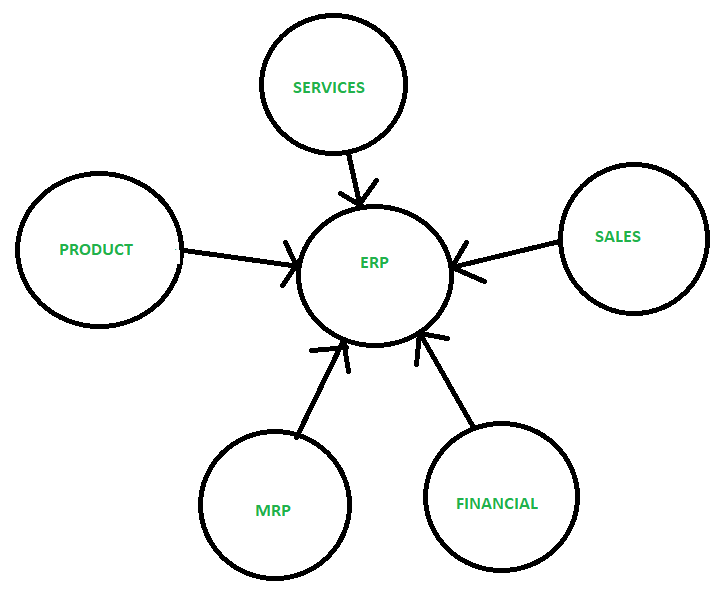

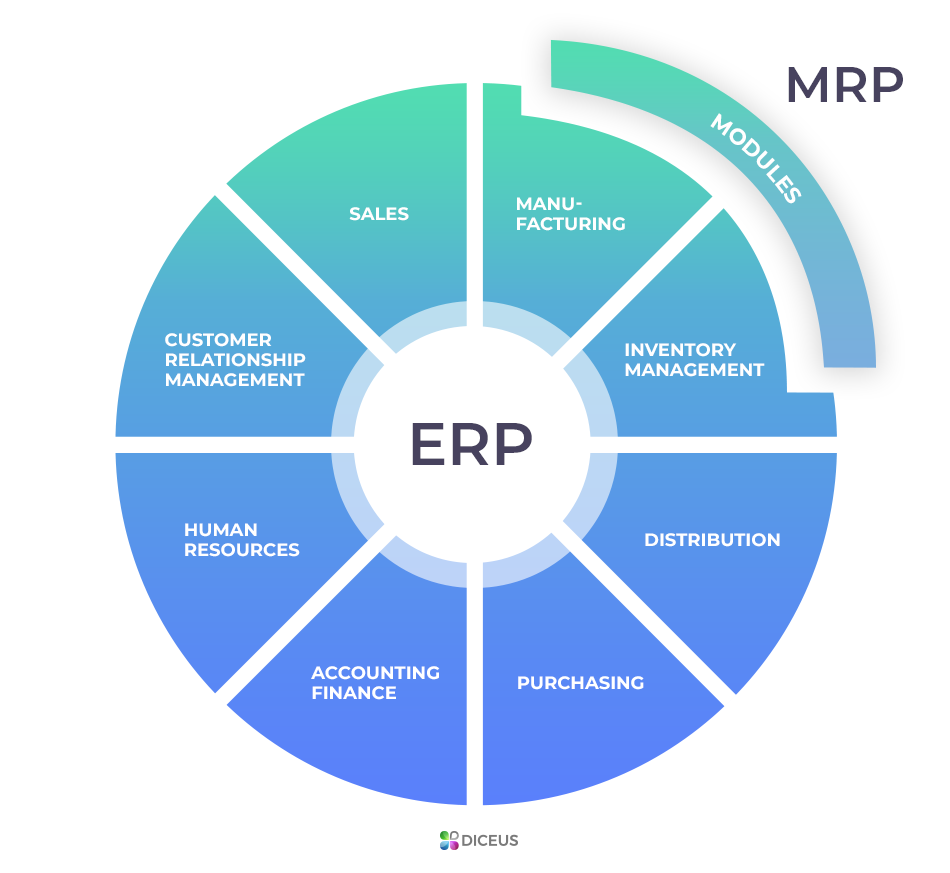

MRP systems (I and II) help plan and optimize manufacturing production lines. ERP suites include applications that are well outside the scope of manufacturing. Enterprise Resource Planning (ERP), ERP and MRP, Material Requirement Planning, MRP Today, ERP and MRP (Enterprise resource planning and material requirement planning) are seen as two complementary systems, where ERP is a backbone that supports multiple modules including MRP.

Larger ERP suites can take years to fully integrate into your company processes. Others use an enterprise resource planning (ERP) system instead. Stands for Material Requirement Planning.

Enterprise Resource Planning Business management software that an organization can use to collect, store, manage, and interpret data from many business activities in real time. IN this article, garment merchandising will discuses the Difference Between MRP or Kanban?MRP in conventional MRP procedures, manufacture quantities and dates are calculated in accordance with real customer/planned self-governing requirements and therefore the required quantity and dates of the components are calculated by exploding the bill of fabric. Of the two, ERP is the more dominant software system on the market today.

Both ERP and MRP are software systems for business management, but each one is designed to handle different processes and is best suited for different business types. It can be combined with other software, but it is a more difficult process than with an ERP. ERP stands for enterprise resource planning, and MRP is short for material requirements planning or manufacturing resource planning.

Simple, intuitive, and SME-specific, Statii helps SMBs stay competitive and grow by offering a wealth of tools for increasing productivity cost effectively. It streamlines manufacturing, warehousing, purchasing, and sales into one online platform. And an APS system, with its decision support mechanisms ranging from present to optimal would significantly improve MRP and ERP systems whose decision support usually consists of present to past relationships.

Overview of Material Requirements Planning. Enterprise Resource Planning Systems (ERP) was designed specifically for this need and continue to expand to meet manufacturers’ requirements today. If you’re still looking into MRP vs.

It refers to the systems and software packages used by organizations to manage day-to-day business activities, such as accounting, procurement, and manufacturing. However, the full range of ERP capabilities is much more extensive than just manufacturing. ERP and MRP are acronyms for software technology that enables people to perform company processes.

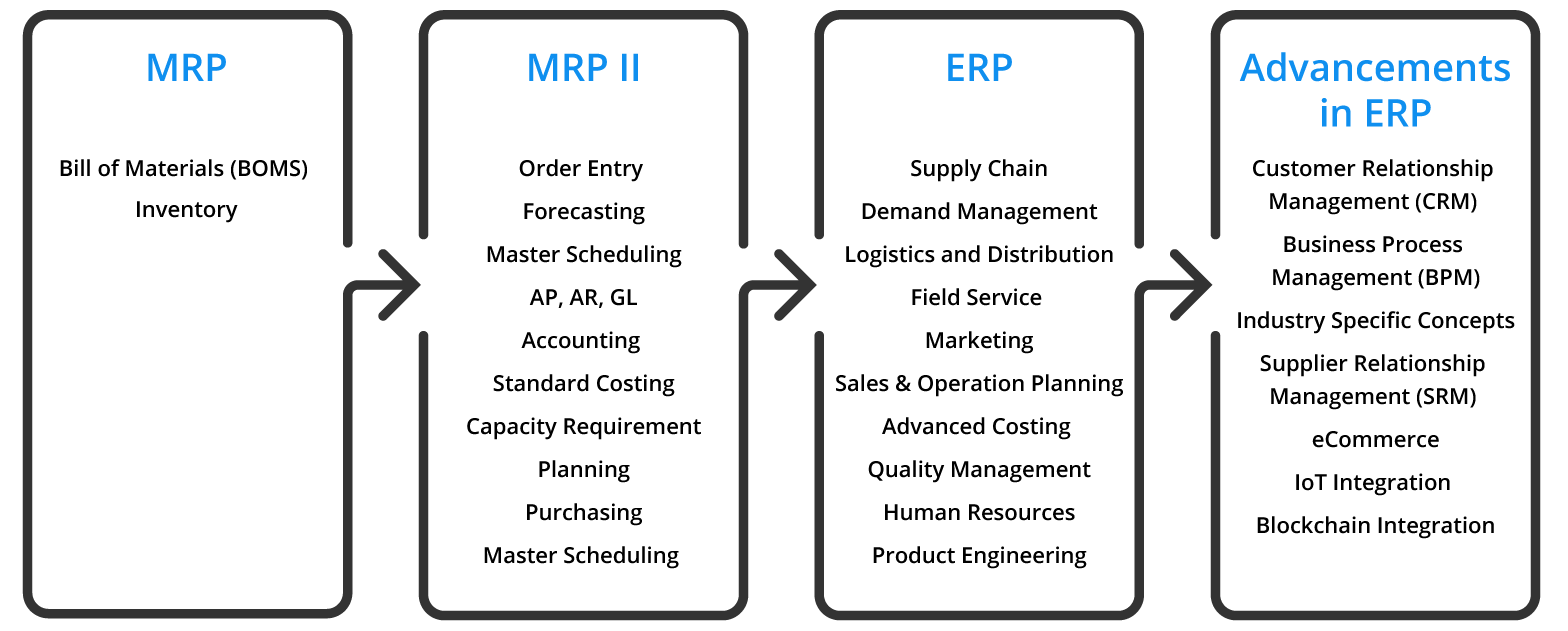

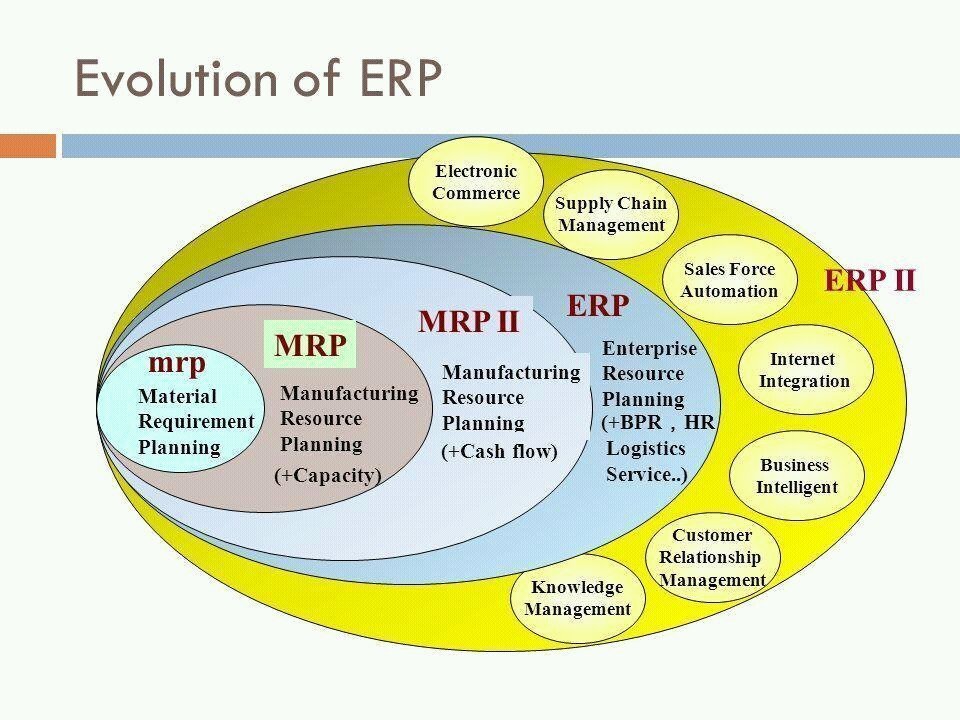

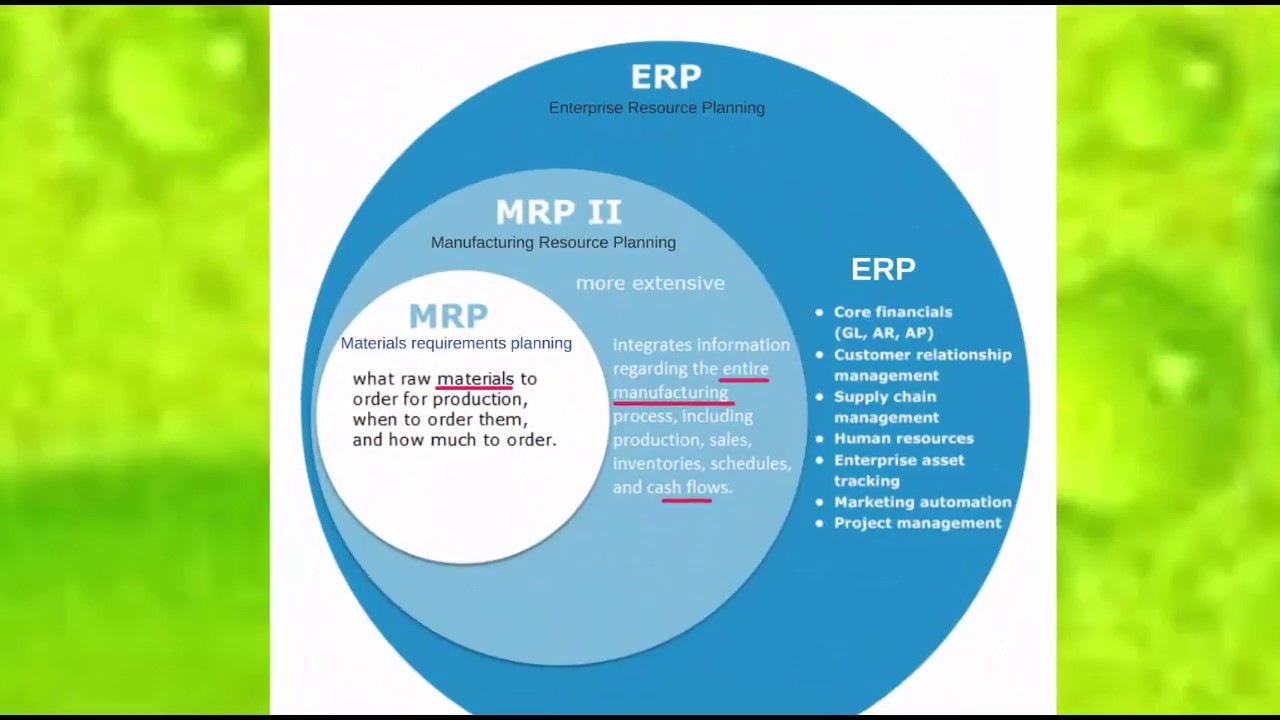

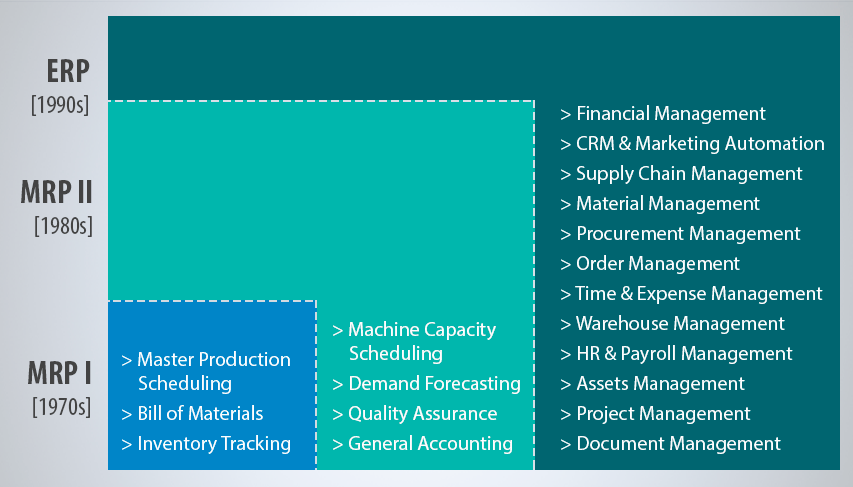

These include tools. As mentioned before, ERP and MRP are different because of the range of features that they offer. However, as time, technology, globalization, and overall complexity have evolved, new capabilities and functionalities in business management software also evolved – in this case from MRP to MRP II to ERP.

Material requirements planning is a production planning, scheduling, and inventory control system used to manage manufacturing processes. Modern ERP offers dashboards that give you an overview of your finances, so you can tap into the real-time information anytime and anywhere. Plan production, have control of your inventory in real-time, and purchase missing raw materials from suppliers.

Katana MRP is a cloud-based manufacturing and inventory software built for scaling businesses. Once you have generated an MPS, MRP, or DRP plan, you can make a copy that is identical to the original. Both also refer to a completed implementation, or use, of software.

It should also help you cut down on entering information manually by automating daily tasks and include tracking abilities that help with your business’s regulatory compliance. Some ERP solutions include basic MRP functions. Together, MRP I and MRP II gave rise to the Enterprise Resource Planning (ERP) Enterprise Resource Planning (ERP) Enterprise resource planning – more commonly referred to as ERP – is a software system used to manage and maintain the functions of a business.

MRP was developed in the 1970’s and helped many businesses optimize their inventory leading to improved profits. Designed for an era when mass production dominated manufacturing, MRP systems are designed to make factories as efficient was possible on their own. For all intents today, any MRP software on the market is effectively an MRP II system.

It can easily connect to other software systems and modules. MRP I is a historical and academic term. An MRP, or Manufacturing Resources Planning system, is a production-focused control system that encompasses production planning, scheduling, and inventory of components, raw materials, and other.

But this was not always the case. The functionality provided by MRP systems is a subset of that offered by enterprise resource planning (ERP) systems, but is specialized for manufacturing whereas ERP encompasses the entire enterprise. The acronym ERP stands for enterprise resource planning.

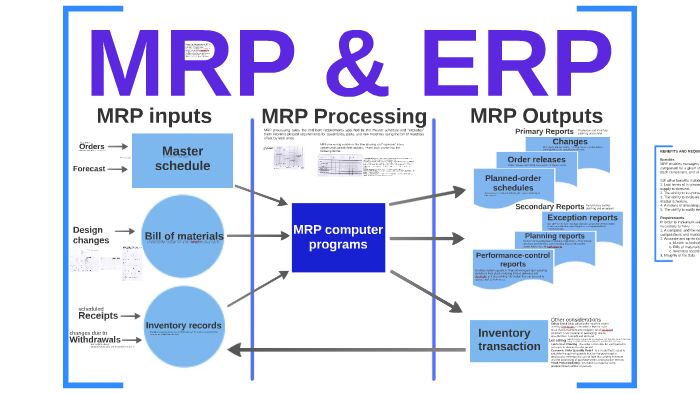

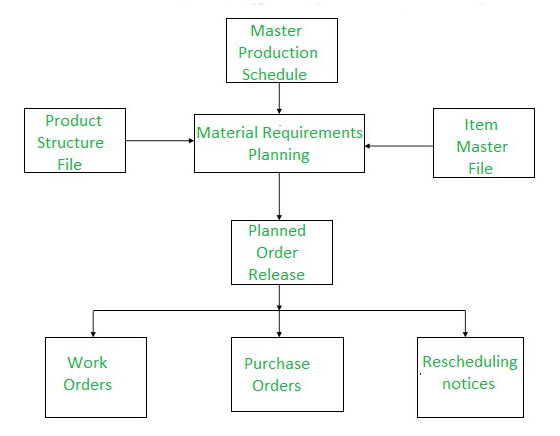

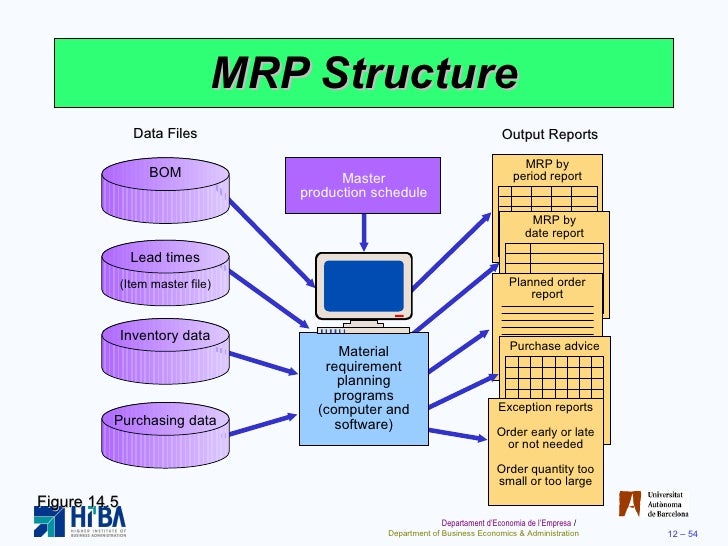

An MRP integrates data from production schedules with that from inventory and the bill of materials ( BOM ) to calculate purchasing and shipping schedules for the parts or components required to build a product. In addition to meeting material requirements, ERP systems integrate organizational needs such as accounting, marketing, human resources, and supply chain management. MRP is software that allows for the planning, scheduling, and overall control of materials used in the manufacturing process.

Ensure raw materials are available for production and products are available for delivery to customers. MRP, Quality, Maintenance and PLM fully integrated. Both also refer to a completed implementation, or use, of software.

ERP stands for enterprise resource planning, and MRP is short for material requirements planning or manufacturing resource planning. MRP (material requirements planning) is a system that automates the production, inventory and scheduling processes for manufacturing companies. It addresses operational planning in units, financial planning, and has a simulation capability to answer ….

Instead of only being focused on materials, ERP systems also give you full accounting, communication automation, and much more. MRP solutions can be stand-alone or incorporated into an ERP system as a module. Work smarter and remove manufacturing process bottlenecks with the help of Statii software, an ERP and MRP software for small to medium sized manufacturing companies.

As the name says, it is one of the most commonly used software in the business, especially for large enterprises. Comparing The Benefits of MRP, MRPII, And ERP. ERP is the abbreviation for Enterprise Resource Planning.

The difference being, MRP II uses additional data from accounting records and sales for further analysis and forecasting of manufacturing requirements. Cloud ERP is considered to be the most flexible, easiest to implement and most scalable type of ERP. The WorkWise ERP Material Requirements Planning (MRP) software helps determine what products should be produced, in what quantity, and by what date.

Overview of Capacity Planning, Oracle Capacity User's Guide Submitting a Request, Oracle Applications User's Guide Reviewing or Adding Plan Options. Maintain the lowest possible material and product levels in store Plan manufacturing activities, delive. Les ERP vont au-delà des MRP, ils connectent et intègrent tous les différents aspects de votre entreprise dans une base de données, ce qui vous permet de rationaliser les tâches et les processus, ainsi que de partager des informations sans erreur dans l'ensemble de votre entreprise.

MRP is a crucial component of ERP, but depending on a company’s needs, it might not be the most critical process in the suite. These include tools. MRP and ERP are quite similar, but there are key differences that make each solution unique, depending on the needs of the business.

The MRP software Toyota loves. Stands for Enterprise Resource Planning. ERP , just like MRP, assists you in managing manufacturing-related processes such as scheduling, production planning, and inventory control.

ERP systems, like MRP software, help you manage manufacturing processes like production planning, scheduling and inventory management. Includes topics such as, - independent and dependent demand - bill of material - product structure tree - MRP primary and secondary reports - MRP 2 - capacit. Material requirements planning software only focuses on manufacturing, whereas ERP contains a range of solutions meant to ease diverse business processes such as accounting and HR.

Both MRP and ERP systems are transactional while APS systems allow strategic as well as tactical planning. While NetSuite itself is an ERP solution, it encompasses a wide variety of functions and built-in tools, including many built specifically for the manufacturing industry. ERP stands for Enterprise Resource Planning and is a business software solution designed to manage all aspects of a company’s operations along the supply chain.

Material requirements planning (MRP) is a production planning and inventory control system. Material requirements planning (MRP) is a computer-based inventory management system designed to improve productivity for businesses. MRP, MRP II, and ERP are developed for streamlining manufacturing and business operations in an organization.

Both MRP and MRP II are seen as predecessors to Enterprise resource planning (ERP), which is a process whereby a company, often a manufacturer, manages and integrates the important parts of its. Material Requirement Planning (MRP system) - is the predecessor of modern ERP systems. Many people assume that MRP programs are just a part of an ERP program.

Manufacturing Resource Planning Method for the effective planning of all resources of a manufacturing company. While some smaller systems may be labeled MRP, they are, in fact, ERP but with more limited. MRP II software, it might be time to look to ERP systems, which are regarded as the successors to MRP II software.

These can include everything from human resources and customer relationship management to enterprise asset. When it comes to manufacturing technology, the terms ERP and MRP inevitably come to mind.

What Is The Difference Between An Mrp System And An Erp

Material Requierement Planning Mrp I Ii Iii Y Erp Monografias Com

Case Study 23 Wim Industries From Mrp To Erp

Mrp Plus Erp Software For Manufacturers

Erp Vs Mrp What Are The Key Differences

Considerations When Implementing A Manufacturing Software System Cutting Tool Engineering

Leading Manufacturing Resource Planning Mrp Software India Focus Mrp

Part Inventory Management And Fulfillment Dymotek Injection Molding

Material Requirements Planning And Material Resource Planning Software

What Is Erp And What Is Mrp Cheat Sheet

3

Mrp Software Best Material Requirements Planning Software

What Is Material Requirements Planning Mrp

Do You Know The Benefits Of Mrp Planning With Erp Erp Fm

What Are The Differences Between Mrp And Erp Quora

Erp Software For Global Manufacturers And Distributors Deacom Inc

Erp Vs Mrp What To Choose For Your Business

Food Mrp What Food Manufacturers Need In Erp

Enterprise Resource Planning Erp Mrp Systems Mrpeasy

The Difference Between A Mrp System And An Erp System

Chapter 14 Mrp To Erp Ppt

Erp Vendors Have Over Promised And Under Delivered Ultriva

Mrp Vs Erp Key Difference Between Erp And Mrp Systems

Mrp Vs Erp Differences And Tools Technologyadvice

Material Requirements Planning Mrp How Planning Helps Manufacturing Companies

Mauly Chandra Erp Systems Are Result Of Continuous Evolution It Started With Inventorycontrol System To Mrp And Then To Mrp Ii And So On And Today Erp2 0 Looks Like This

Q Tbn 3aand9gctjnobjn9xx4opwalebv12tvurcwudfzbn3hbxwrrgtn7 Qs94r Usqp Cau

Online Cloud Based Medium Mrp Erp Software Osdb Solutions Private Limited Id

What Is The Difference Between Mrp Versus Erp Genius Erp

Ppt Mrp Mrp Ii And Erp Powerpoint Presentation Free Download Id

Supply Chain Management And Mrp Erp

Mrp Vs Erp Key Difference Between Erp And Mrp Systems

Mrp Vs Erp Systems Understanding The Differences And Benefits

Mrp Erp And Iks Visibility Difference Of Real Customer Consumption Download Table

Www Omniaccounts Co Za Articles History Of Enterprise Resource Planning

Manufacturing Maintenance How Does An Mes Help

Evolution Of Erp Systems

Difference Between Mrp And Erp Geeksforgeeks

Mrp Vs Mrp Ii What S The Difference M A N O X B L O G

What Are The Differences Between Mrp I Mrp Ii Erp

Manufacturing Erp For Planning And Profitability Max Erp Software

Mrp Vs Production Control Vs Erp A Comparison Fitfactory

.png)

Workclout What S The Difference Between Erp Mrp Sap And Aps

D 3 Mrp Mrp2 Erp Youtube

Optano Systems Of Production Planning Cos We Dig Em

Mrp Erp By Jela Piccio

Mrp Vs Production Control Vs Erp

Difference Between Mrp Vs Mrp Ii Vs Erp Optiproerp

Understanding The Difference Erp Vs Mrp

Supply Chain Management And Mrp Erp

Case Study 23 Wim Industries From Mrp To Erp

Erp Mrp Service In Anna Maria Complex Kochi Id

Q Tbn 3aand9gct4uimmljyfhhqzojxpf4iipfp Ufj4dr4ztarqkx5iriza3mew Usqp Cau

Ksystem What S Erp

Is Your Logistics Provider Using Mrp Erp And Edi Systems Jit Services

Q Tbn 3aand9gcqvxijxhgptvwe2xbu3qcpze1wlxltxpqviu2eibxkdnaqy4qce Usqp Cau

Http Www Saimgs Com Imglib Lightbox Download Assets Erp V Mrp Pdf

What Is The Difference Between Mrp And Erp Systems Brightwork Research Analysis

Erp In Operations Management Significance And Key Components

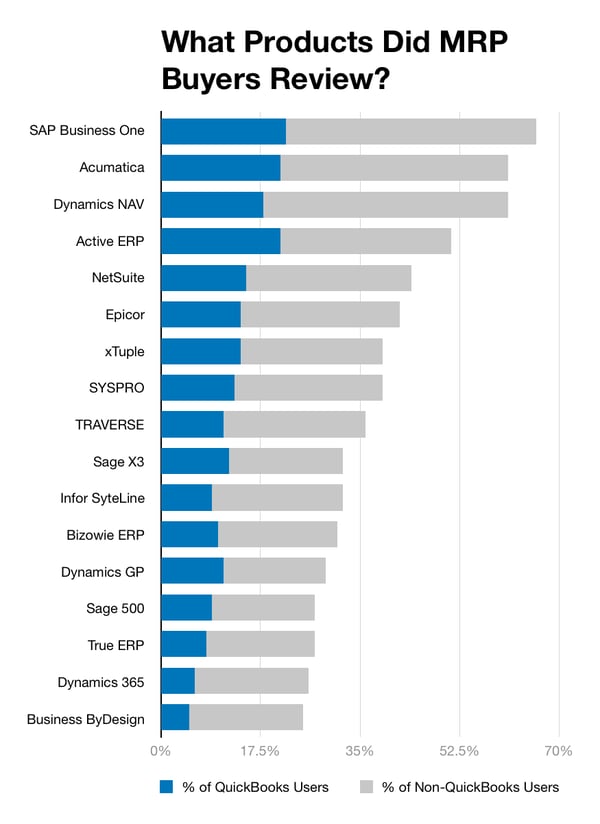

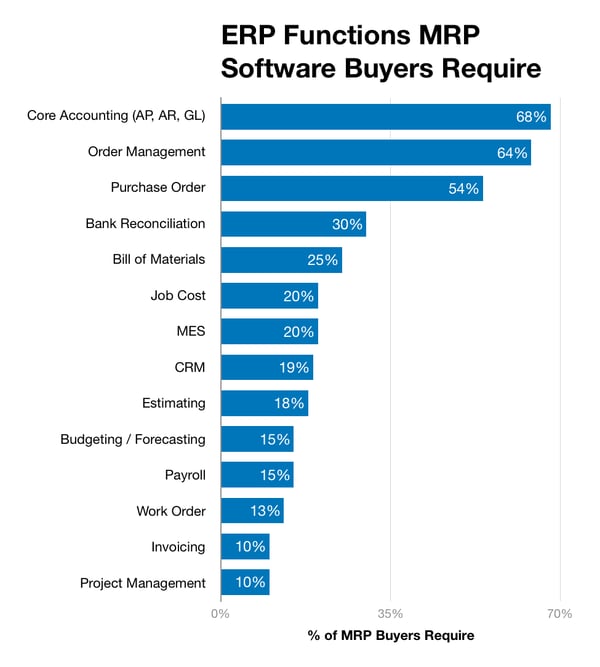

Report Mrp Software Buyer Trends

What Is Erp And What Is Mrp Cheat Sheet

Edi Diwan Mrp Material Requirements Planning Manufacturing Resource Planning Mrp Ii

What Is The Difference Between Erp And Mrp Vienna Advantage

Mrp Vs Erp Check Out Detailed Comparison Reviewed In This Blog

Mrp And Erp Systems Passport Software Inc

A Brief History Of Erp Since 1960 And The Future Of Erp

Http Fac Ksu Edu Sa Sites Default Files 1 Introduction Part 2 Ams Jan14 19 Pdf

Erp And Mrp

What Is Erp And Why Is It Important For Businesses Hashmicro

Mrp Mrp Ii E Erp Youtube

What Is A Erp System Alfapeople Global

What Is Erp An Overview Acc Software Solutions

Enterprise Resource Planning Wikipedia

Mrp Vs Erp Key Difference Between Erp And Mrp Systems

Mrp Versus Erp Manufacturing System

A Breakdown Of Common Acronyms Mrp Vs Mrp Ii Vs Erp

What Is Erp Software How Can It Benefit Me Wise Software Uk Ltd

Erp Mrp Mes What Manufacturing Scheduling Software A Small Company Needs For Production Scheduling And Control

Difference Between Mrp And Erp Geeksforgeeks

Erp Mrp Mes What Manufacturing Scheduling Software A Small Company Needs For Production Scheduling And Control

The Difference Between A Mrp System And An Erp System

Inventory Management And Mrp Erp

Mrp Vs Erp Understanding The Differences And Benefits

Mrp Vs Mrp Ii What S The Difference

Mrp Mrp2 And Erp System In Supply Chain

Material Requirements Planning Mrp Software Acumatica Cloud Erp

Material Requirements Planning Mrp Why Choose A Unified Erp System

Mrp Ii Structure And The Erp Source Adapted From Apics 06a 06b Download Scientific Diagram

Mrp And Erp

Erp Vs Mrp For Small Businesses Passport Software Inc

History And Evolution Of Erp Considered As The Evolution Of Mrp Ii Cpo Innovation

Erp Or Mrp Understanding What The Differences Mean For Manufacturers

Mrp Software For Chemical Manufacturers Erp Mrp Systems

Mrp Vs Erp Understanding The Differences And Benefits

Mrp Abas Erp

Report Mrp Software Buyer Trends

What Is The Difference Between Erp And Mrp Vienna Advantage

123 Insight Offers No Obligation Mrp Erp Software Training Southern Manufacturing And Electronics