Erp Mrp

What Is A Erp System Alfapeople Global

The Complete History Of Erp Its Rise To A Powerful Solution

Manufacturing Erp And Industry 4 0 Mrpeasy

Difference Between Mrp Vs Mrp Ii Vs Erp Optiproerp

Case Study 23 Wim Industries From Mrp To Erp

Erp Vs Mrp For Small Businesses Passport Software Inc

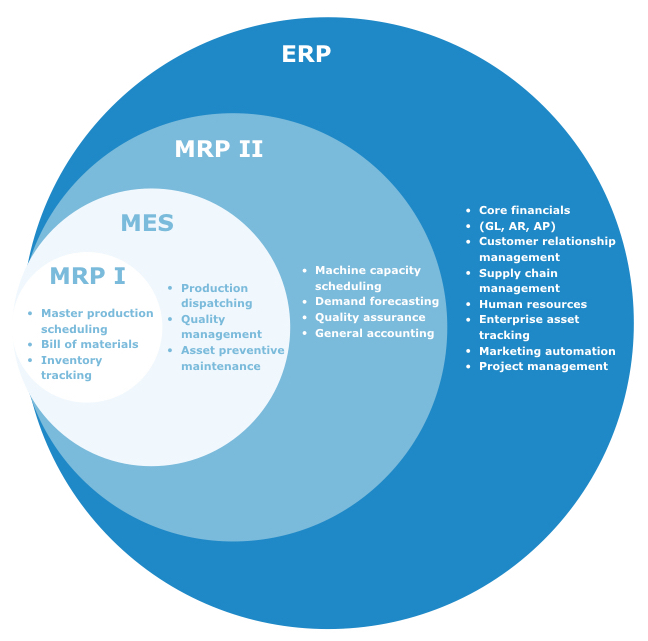

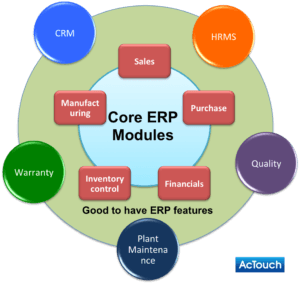

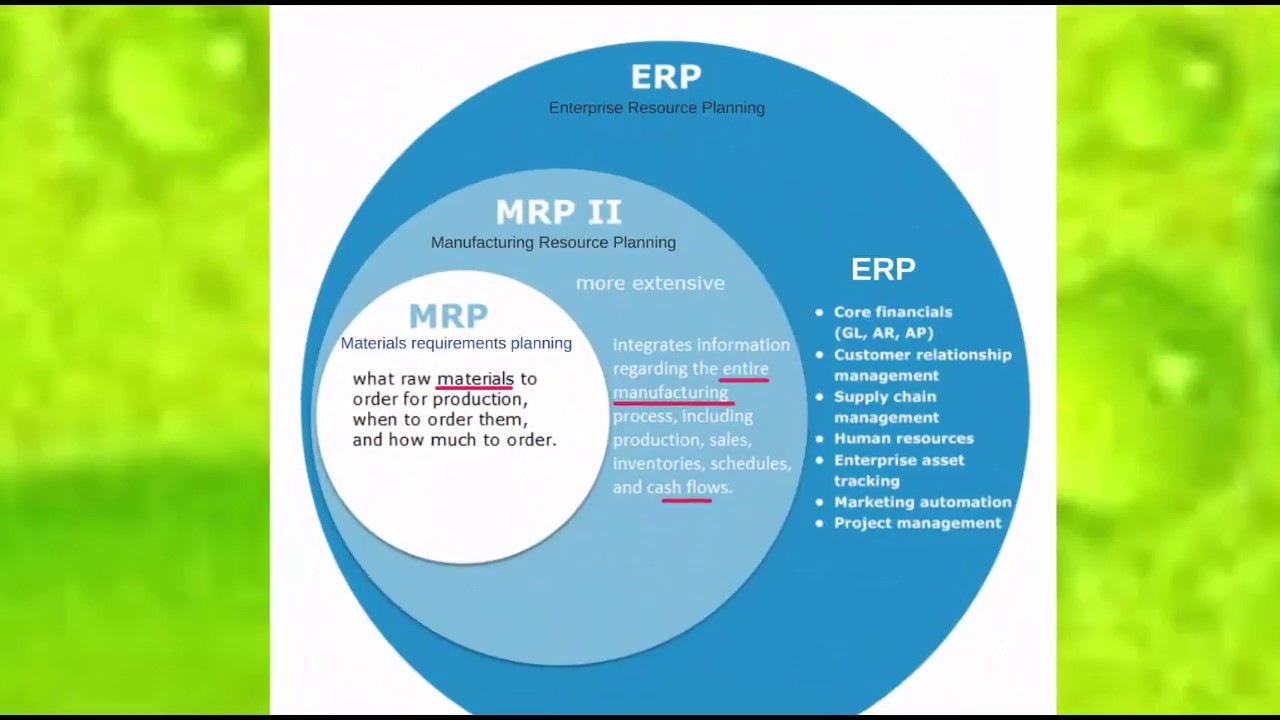

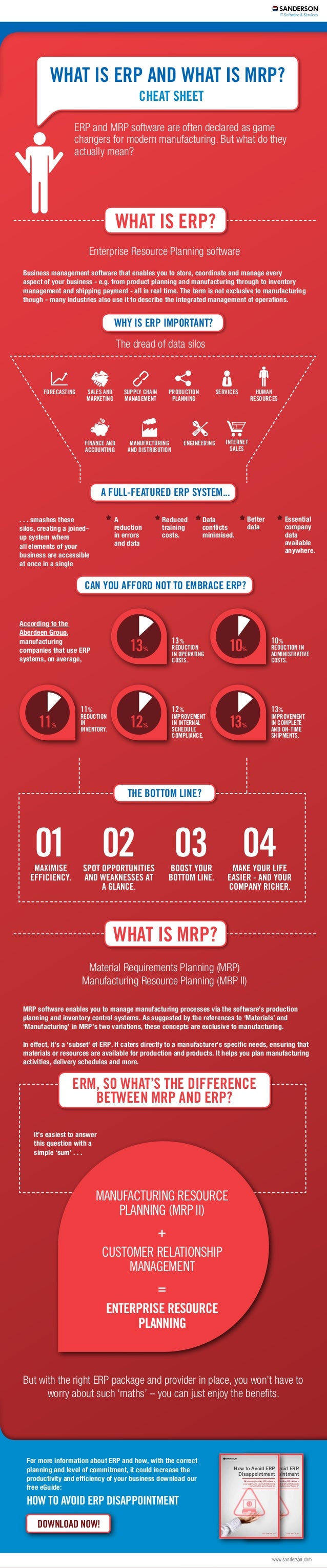

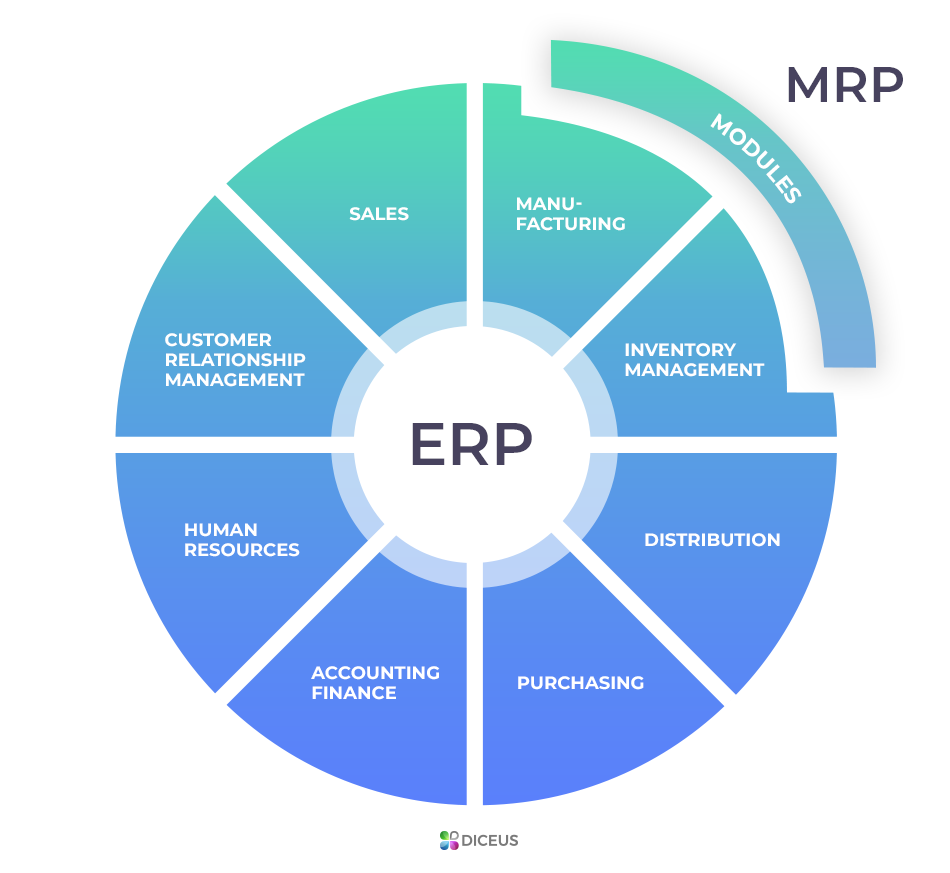

ERP (Enterprise Resource Planning) is an extended version of MRP II, but a lot more comprehensive as it includes all core business functions and processes, including manufacturing operations.

Erp mrp. In addition to production and inventory, ERP systems also support financial and accounting management, sales, CRM, HR, service and support, and more. ERP and MRP are acronyms for software technology that enables people to perform company processes. Both MRP and ERP systems are pieces of software that help you run your business through smart forecasting and your chosen business priorities, but MRP has a purely manufacturing focus as opposed to ERP, which spans across a business as well as supply chain.

That is the reason why these solutions are adopted widely. As standalone system, MRP predominantly deals with the stock administration & manufacturing scheduling areas of the enterprise. Enterprise Resource Planning Software – Summary.

What are the Key Differences?. It’s a business process management software that manages and integrates a company’s financials, supply chain, operations, reporting, manufacturing, and human resource activities. The two acronyms sound so similar that they are often mistaken as being the same thing.

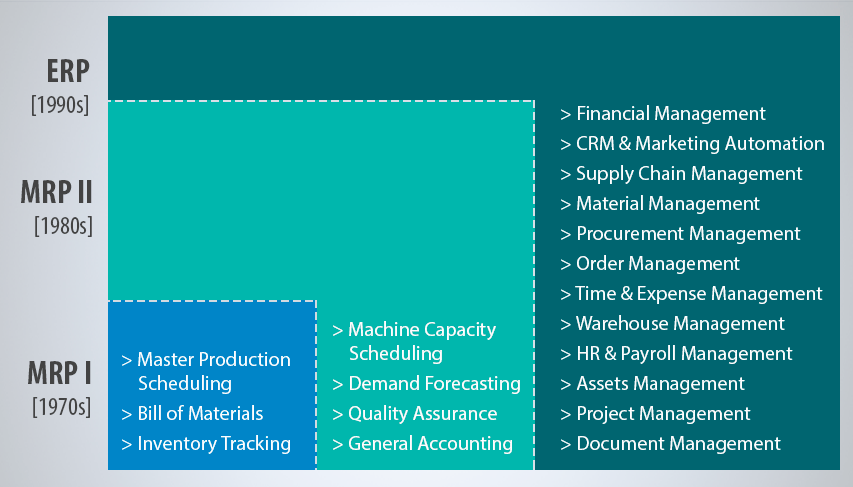

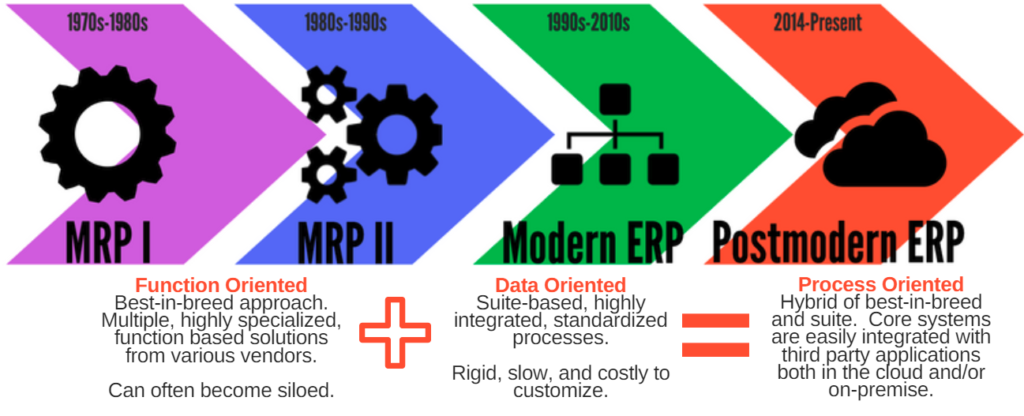

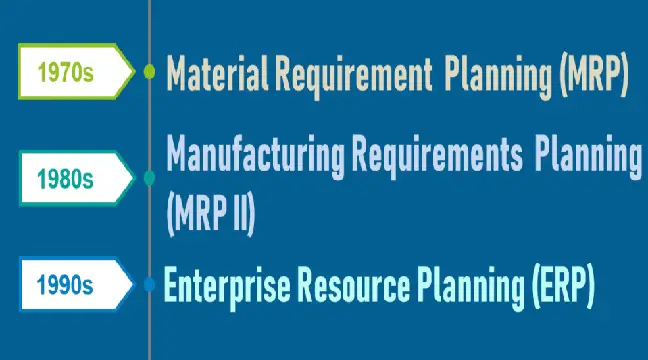

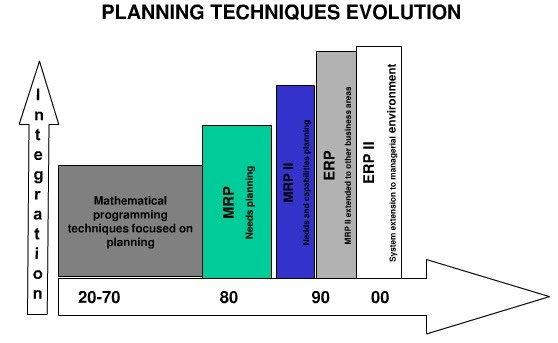

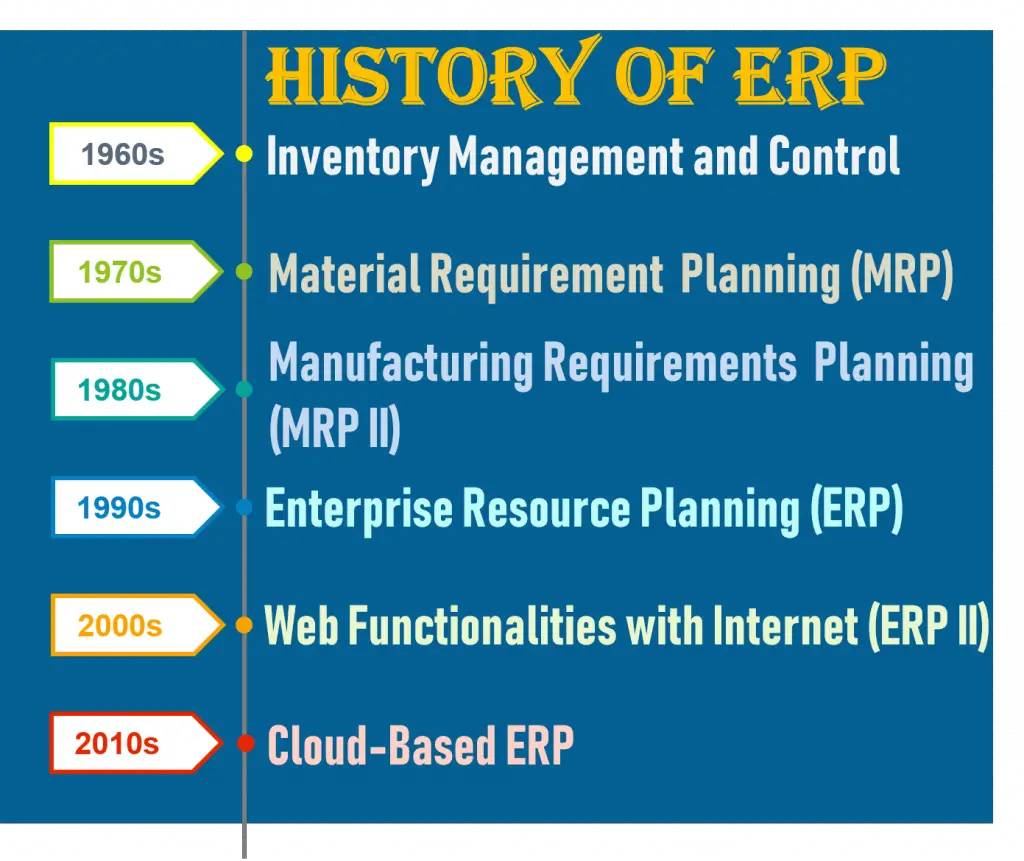

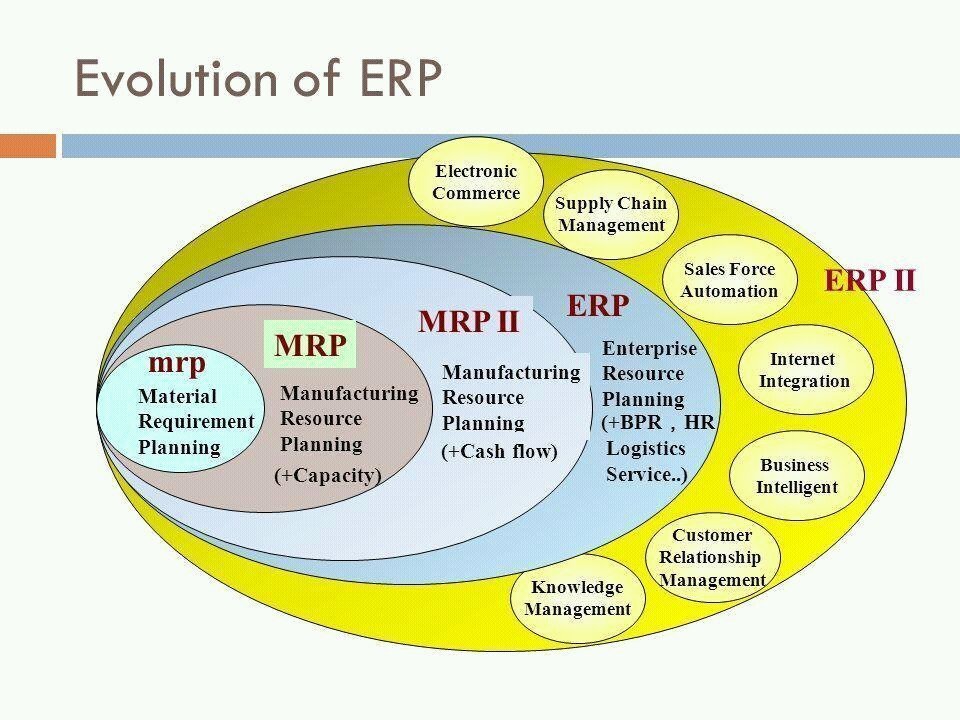

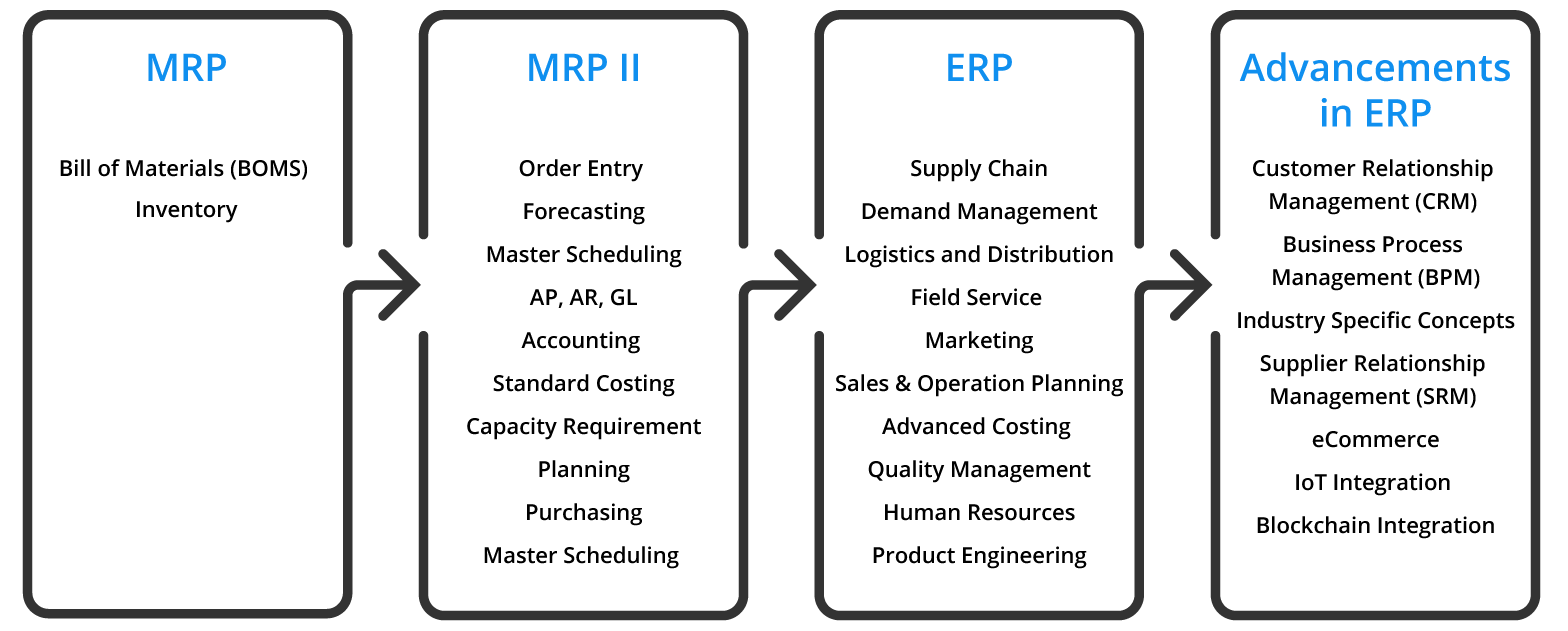

The Gartner Group first used the acronym ERP in the 1990s to include the capabilities of material requirements planning (MRP), and the later manufacturing resource planning (MRP II), as well as computer-integrated manufacturing.Without replacing these terms, ERP came to represent a larger whole that reflected the evolution of application integration beyond manufacturing. It can be combined with other software, but it is a more difficult process than with an ERP. ERP — Enterprise Resource Planning:.

Nearly every ERP system includes a basic planning module:. Enterprise Resource Planning Systems (ERP) was designed specifically for this need and continue to expand to meet manufacturers’ requirements today. Material Requirement Planning (MRP system) - is the predecessor of modern ERP systems.

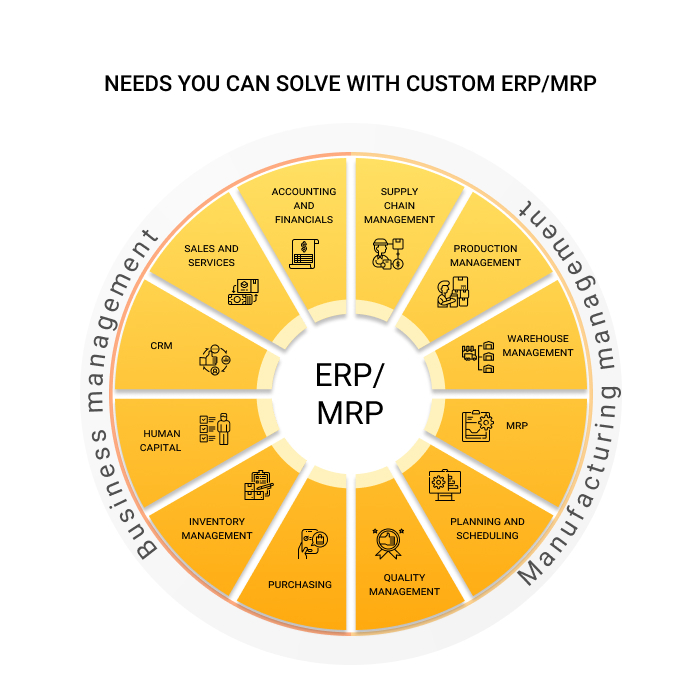

Material requirements planning software only focuses on manufacturing, whereas ERP contains a range of solutions meant to ease diverse business processes such as accounting and HR. In addition to meeting material requirements, ERP systems integrate organizational needs such as accounting, marketing, human resources, and supply chain management. ERP는 사실 생산 시의 효율적 관리를 돕기 위한 시스템인 MRP에서 비롯되었다.

Not a day goes by in the life of a manufacturing professional that we don’t hear the term Material Requirements Planning, or its more common abbreviation MRP. Any system – MRP or ERP – needs to also provide security at user level to ensure that the right employees have access to the right information. However, Enterprise Resource Planning (ERP) and Material Requirements Planning (MRP) are two very different systems.

Designed for an era when mass production dominated manufacturing, MRP systems are designed to make factories as efficient was possible on their own. The biggest difference between MRP and ERP is that material requirements planning (MRP) functions as an a la carte, single-function manufacturing system that focuses on inventory levels, while ERP is an integrated system that supports several modules, applications and integrations throughout an organization. This tutorial will help you understand SAP MRP process overview, its outcome, and levels of planning.

Many people assume that MRP programs are just a part of an ERP program. ERP and MRP are acronyms for software technology that enables people to perform company processes. Materials Requirement Planning (MRP) The objective of MRP is to ensure material availability for the requirements.

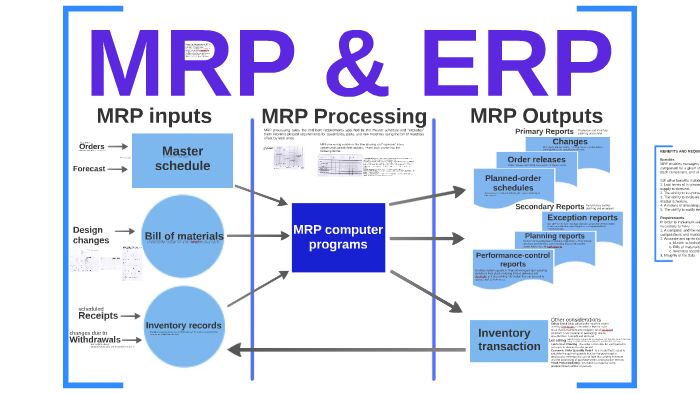

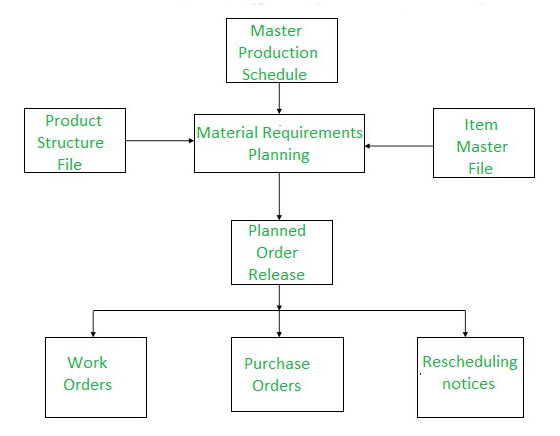

Material requirements planning (MRP) is a production planning and inventory control system. Both ERP and MRP are software systems for business management, but each one is designed to handle different processes and is best suited for different business types. The MRP system was developed in the 1970s and focused primarily on the inventory of production components.

Erp mrp Schedule-Based (Push) Manufacturing, production is controlled by a computer schedule. An MRP system is intended to simultaneously meet three objectives:. I find that people tend to blur the lines between ERP, MRP, and PLM.

Two popular types of software for streamlining business processes are enterprise resource planning (ERP) and manufacturing resource planning (MRP). Ensure raw materials are available for production and products are available for delivery to customers. ERP , just like MRP, assists you in managing manufacturing-related processes such as scheduling, production planning, and inventory control.

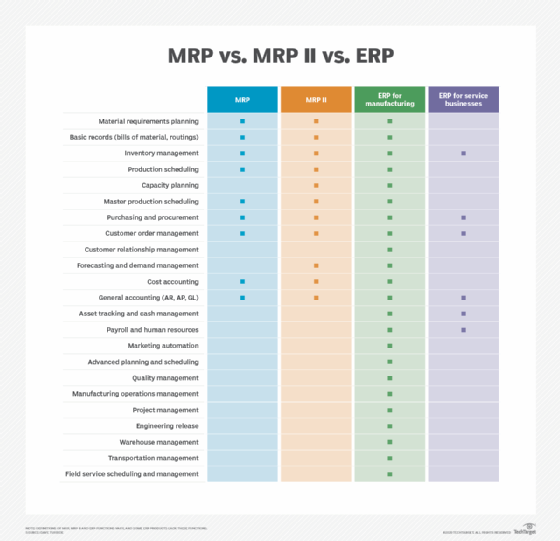

Both MRP and MRP II are seen as predecessors to Enterprise resource planning (ERP), which is a process whereby a company, often a manufacturer, manages and integrates the important parts of its. Together, MRP I and MRP II gave rise to the Enterprise Resource Planning (ERP) Enterprise Resource Planning (ERP) Enterprise resource planning – more commonly referred to as ERP – is a software system used to manage and maintain the functions of a business. ERP stands for enterprise resource planning, and MRP is short for material requirements planning or manufacturing resource planning.

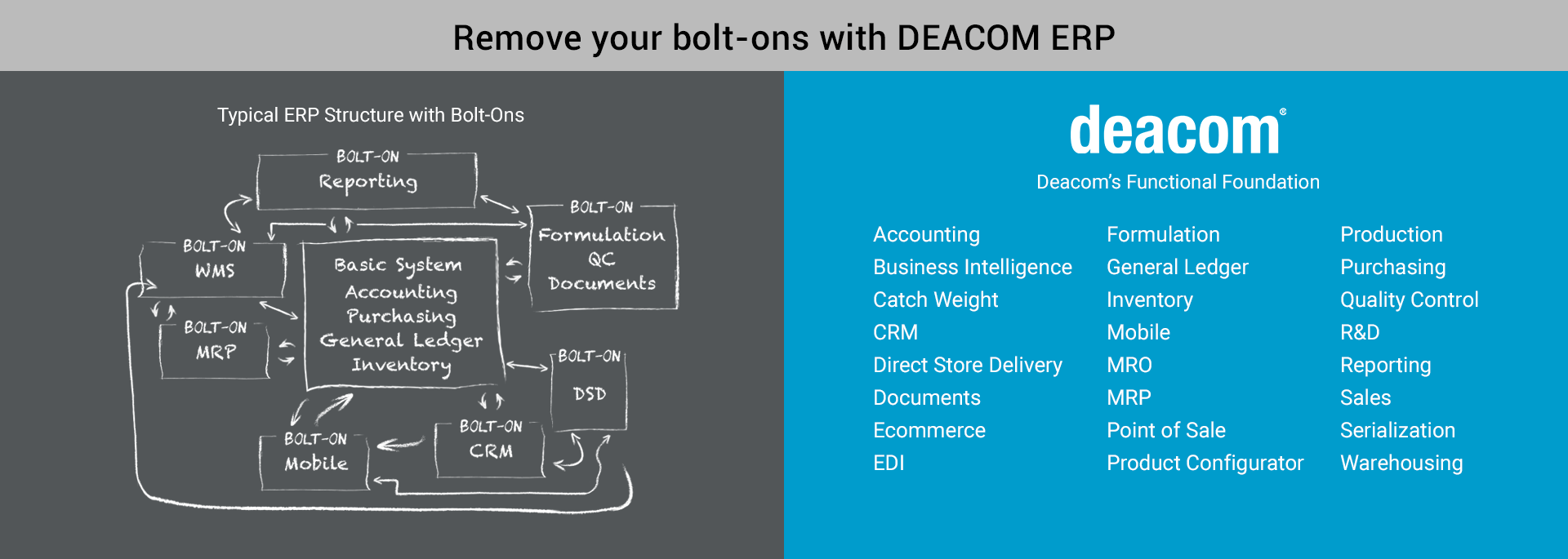

While some smaller systems may be labeled MRP, they are, in fact, ERP but with more limited. Choosing the right ERP software system can put you in a bit of a dilemma. Whereas MRP is more of a solo software solution, an ERP is integrated and can speak to multiple systems.

Though they specialize in ERP software, they focus mainly on the service end of the process. 역시 ERP가 어떻게 시작되었는지 그 역사를 알면 이 시스템에 대해서도 이해하기가 쉽다. Most manufacturers use an organizational system called material requirements planning (MRP).

ERP software program can pick the areas the place enhancements are needed and needed. MRP is software that allows for the planning, scheduling, and overall control of materials used in the manufacturing process. Each have their own advantages, use cases, and even disadvantages.

Most MRP systems are software-based, but it is possible to conduct MRP by hand as well. ERP is an acronym that stands for enterprise resource planning (ERP). One of the biggest driving factors for the need for an enterprise-class ERP system revolves around finance/accounting.

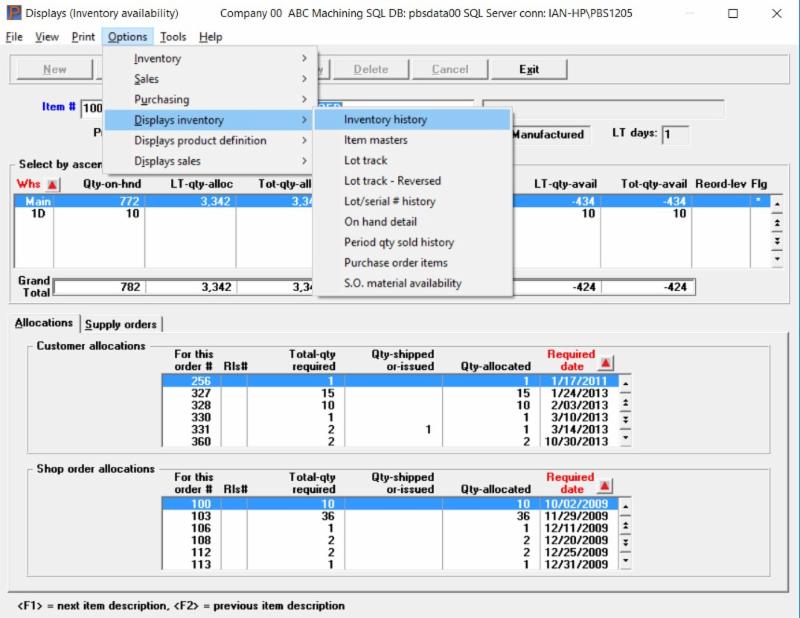

Both also refer to a completed implementation, or use, of software. Comparing The Benefits of MRP, MRPII, And ERP. Among these features is Demand Planning, where an MRP can be used to balance demand and supply.

Each and every section mentioned above needs the ability to either block access or provide read-only access. MRP programs, however, rely heavily on manual input from their users to create production schedules. Quantities of fabricated parts or sub-assemblies are scheduled and completed based on their consuming (higher-level) products start date.

Simple, intuitive, and SME-specific, Statii helps SMBs stay competitive and grow by offering a wealth of tools for increasing productivity cost effectively. MRP is a crucial component of ERP, but depending on a company’s needs, it might not be the most critical process in the suite. A complete guide outlining the differences between ERP and MRP systems to help you understand what solution best suits your business.

Material Requirements Planning (MRP) ERP software for manufacturing and distribution From sales order to shipping and every step in between, OptiProERP’s Material Requirements Planning (MRP) software helps manufacturers operate more efficiently and more profitably. As mentioned before, ERP and MRP are different because of the range of features that they offer. Make sure that you use an ERP that can easily integrate with your tech stack.

ERP stands for Enterprise Resource Planning and is a business software solution designed to manage all aspects of a company’s operations along the supply chain. But this was not always the case. A complete ERP suite also includes enterprise performance management, software that helps plan, budget, predict, and report on an organization’s financial results.

Material Requirements Planning (MRP) is the know-all and tell-all for manufacturing including the inventory, planning and scheduling details. MRP can be termed as a subset of ERP as ERP solutions have MRP modules. A related concept that expands on MRP is enterprise resources planning (ERP), which uses computer technology to link the various functional areas across an entire business enterprise.

ERP systems tie together a multitude of business processes and enable the flow of data between them. MRP is more of a solo software. Offering seamless management of production, stock, customers, purchases, finances, and your team.

ERP는 경영학 관점에서 보면 일종의 MIS(Management Information System)이라고 할 수 있는데. A MRP system focusses on the processes from:. Work smarter and remove manufacturing process bottlenecks with the help of Statii software, an ERP and MRP software for small to medium sized manufacturing companies.

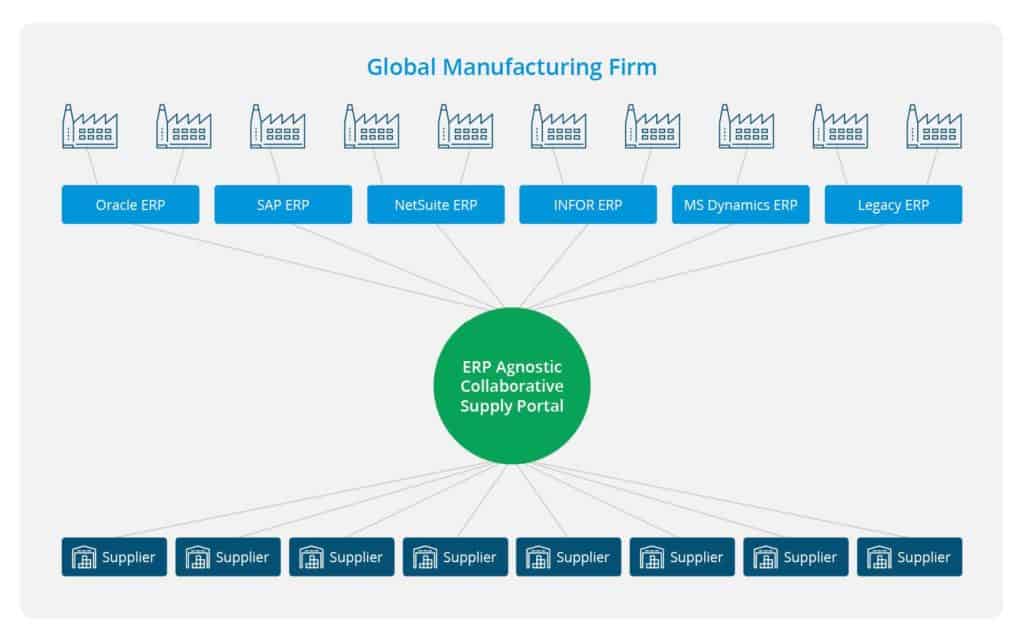

Because data and scheduling resources located within an enterprise resource planning (ERP) are often used to facilitate materials requirements planning (), ERP and MRP are closely related in the business world.An ERP is a software platform used to plan and keep records of business resources like finances, workforce, materials, and property. Cloud ERP is considered to be the most flexible, easiest to implement and most scalable type of ERP. Depending on the industry type, both MRP and ERP offer time and cost savings to businesses.

MRP was developed in the 1970’s and helped many businesses optimize their inventory leading to improved profits. In a similar manner, enterprise resource planning can be thought of a system that encompasses all of the capabilities of manufacturing resource planning, as well as all the other business-related capabilities that MRP simply can't deal with such as billing, customer service, shipment and delivery, human resources, etc. MRP is a simpler solution than the complex ERP.

ERP stands for enterprise resource planning, and MRP is short for material requirements planning or manufacturing resource planning. Of the two, ERP is the more dominant software system on the market today. While MRP can integrate within an ERP system, they also function perfectly fine on their own.

The purpose of this blog is to summarize the high-level intent of most ERP, MRP and PLM systems. Cloud-based MRP system for small manufacturers (10 - 0 employees) A simple yet powerful self-service manufacturing ERP/MRP software. MRP stands for Materials Requirement Planning and it is one of the most important functions of SAP ERP system.

Both are used to improve how your company handles important resources, from labor to inventory. An MRP, or Manufacturing Resources Planning system, is a production-focused control system that encompasses production planning, scheduling, and inventory of components, raw materials, and other. As a outcome, it may.

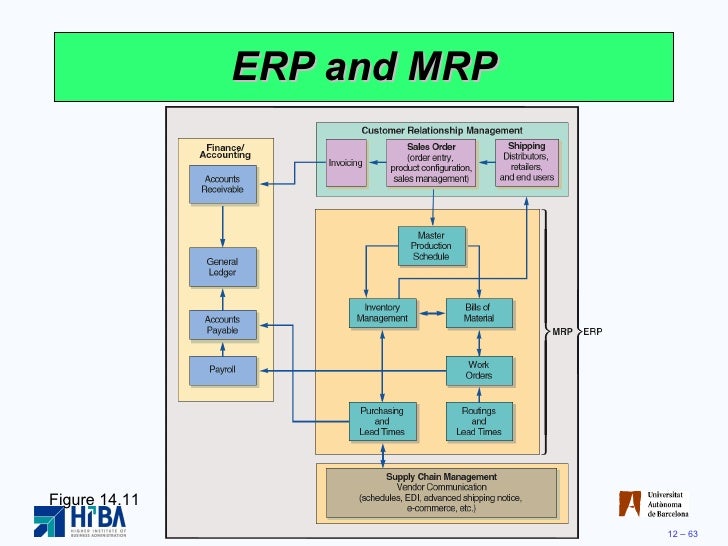

NetSuite is a popular cloud-based ERP solution that houses a multitude of features and capabilities to streamline all business processes. Enterprise Resource Planning (ERP), ERP and MRP, Material Requirement Planning, MRP Today, ERP and MRP (Enterprise resource planning and material requirement planning) are seen as two complementary systems, where ERP is a backbone that supports multiple modules including MRP. Material requirements planning is a production planning, scheduling, and inventory control system used to manage manufacturing processes.

MRP Systems and ERP Systems To make the best choice among existing platforms, it is best to first understand the difference between an MRP and an ERP. There is a strong relationship between ERP and MRP. As the name says, it is one of the most commonly used software in the business, especially for large enterprises.

Both also refer to a completed implementation, or use, of software. The MRP can drive the manufacturing schedule based upon the material that is currently available or the inventory that needs to be purchased. Stands for Material Requirement Planning.

It can easily connect to other software systems and modules. There are always ways to improve your business operations. We are all familiar with the term, and what it means, but how well do we.

When it comes to manufacturing technology, the terms ERP and MRP inevitably come to mind. These include tools. Navy Enterprise Resource Planning (ERP) is the Department of the Navy financial system of record, meaning it provides reliable information for Navy leadership to keep our Navy moving forward.Using sophisticated business management software, Navy ERP streamlines the Navy’s business operations, namely financial and supply chain management.

However, MRP can be usually one among many modules of an ERP system. Where does MRP stop and ERP start?. ERP is the abbreviation for Enterprise Resource Planning.

History of ERP and MRP systems. If you are needing Epicor® MRP training, you are at the right place.Tomerlin-ERP provides all professional services after the sale, including MRP training. Others use an enterprise resource planning (ERP) system instead.

Stands for Enterprise Resource Planning. Experts in enterprise resource planning software discuss some of the most common missteps IT leaders make when choosing, deploying and implementing an ERP system — and what they can do to. An MRP integrates data from production schedules with that from inventory and the bill of materials ( BOM ) to calculate purchasing and shipping schedules for the parts or components required to build a product.

Enterprise Resource Planning Business management software that an organization can use to collect, store, manage, and interpret data from many business activities in real time. Maintain the lowest possible material and product levels in store Plan manufacturing activities, delive. MRP, or manufacturing requirements planning, is a type of computer-based system developed to help manufacturers get the right material in the right quantity at the right time.

Top 7 Make To Order Erp Software In Reviews Features Pricing Comparison Pat Research B2b Reviews Buying Guides Best Practices

Customizable Erp Mrp Erpag

Mrp Vs Erp Key Difference Between Erp And Mrp Systems

Mrp Abas Erp

Manufacturing Maintenance How Does An Mes Help

What Are The Differences Between Mrp I Mrp Ii Erp

Mrp Software For Chemical Manufacturers Erp Mrp Systems

Deacom Erp Software Deacom Inc

What Is The Difference Between Erp And Mrp Vienna Advantage

Manufacturing Software Custom Erp And Mrp Software Development Services

History And Evolution Of Erp Considered As The Evolution Of Mrp Ii Cpo Innovation

Mrp Vs Erp Which Solution Is Right For You Mrpeasy

Erp Vs Mrp 11 Key Features To Consider Before Buying Manufacturing Software Paperpicks Leading Content Syndication And Distribution Platform

Food Mrp What Food Manufacturers Need In Erp

Erp Mrp Mes What Manufacturing Scheduling Software A Small Company Needs For Production Scheduling And Control

A Guide To Erp Infographic Simpler Software

Mrp Vs Production Control Vs Erp

Mrp Erp By Jela Piccio

What Is Erp An Overview Acc Software Solutions

Mrp Vs Erp Check Out Detailed Comparison Reviewed In This Blog

Mrp Abas Erp

Amazon Com Lean Mrp Establishing A Manufacturing Pull System For Shop Floor Execution Using Erp Or Aps Altemir David Books

Material Requirements Planning Mrp And Erp Ppt Video Online Download

Ksystem What S Erp

Material Requirements Planning Mrp Why Choose A Unified Erp System

Mrp Vs Erp Understanding The Differences And Benefits

Enterprise Resource Planning Wikipedia

What Are The Differences Between Mrp And Erp Quora

Ppt Mrp Mrp Ii And Erp Powerpoint Presentation Free Download Id

Mrp Vs Mrp Ii What S The Difference M A N O X B L O G

Mrp Vs Erp Differences And Tools Technologyadvice

Mrp Erp And Iks Visibility Difference Of Real Customer Consumption Download Table

Mrp Plus Erp Software For Manufacturers

Erp Or Mrp Understanding What The Differences Mean For Manufacturers

Mrp Vs Erp Systems Understanding The Differences And Benefits

Mrp Vs Erp Which Solution Is Right For You

Understanding The Difference Erp Vs Mrp

Inventory Management And Mrp Erp

What Is Material Requirements Planning Mrp

Manufacturing Resource Planning And Erp Erp Fm

Mrp Software Best Material Requirements Planning Software

Q Tbn 3aand9gcrf F3liviqat7zrg2evzbl7wcci2yd3vr9xdom0siq80lifcgx Usqp Cau

Q Tbn 3aand9gcsmsrzoiv0fvqekwxwevefnunapyry7lfy5wnm8moav8bheyvgt Usqp Cau

What Is Mrp Ii Manufacturing Resource Planning

Q Tbn 3aand9gcr25uuawvow3006zgfyr2gzlofqezthxhtxmtdizzfsxvxxj5gs Usqp Cau

Mrp Ii Structure And The Erp Source Adapted From Apics 06a 06b Download Scientific Diagram

Q Tbn 3aand9gcqvxijxhgptvwe2xbu3qcpze1wlxltxpqviu2eibxkdnaqy4qce Usqp Cau

The Difference Between A Mrp System And An Erp System

Erp Vendors Have Over Promised And Under Delivered Ultriva

What Is Erp And What Is Mrp Cheat Sheet

Material Requirements Planning Mrp How Planning Helps Manufacturing Companies

Manufacturing Erp For Planning And Profitability Max Erp Software

D 3 Mrp Mrp2 Erp Youtube

123 Insight Offers No Obligation Mrp Erp Software Training Southern Manufacturing And Electronics

The Difference Between A Mrp System And An Erp System

Do You Know The Benefits Of Mrp Planning With Erp Erp Fm

What Is Erp And What Is Mrp Cheat Sheet

Erp And Mrp

What Is The Difference Between Mrp Versus Erp Genius Erp

Case Study 23 Wim Industries From Mrp To Erp

Erp Vs Mrp What To Choose For Your Business

Edi Diwan Mrp Material Requirements Planning Manufacturing Resource Planning Mrp Ii

What Is The Difference Between Erp And Mrp By Gligor Chavdarov Medium

What Is The Difference Between Mrp And Erp Systems Brightwork Research Analysis

Evolution Of Erp Systems

Supply Chain Management And Mrp Erp

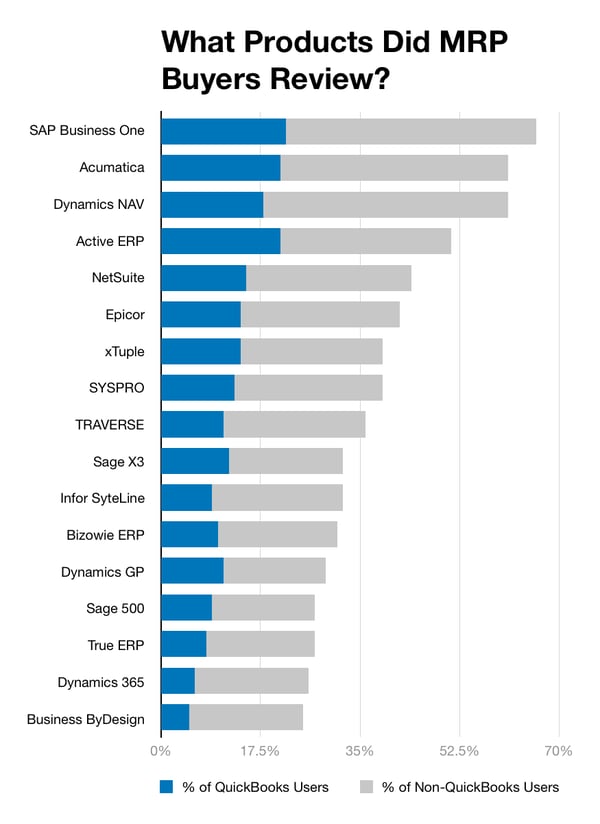

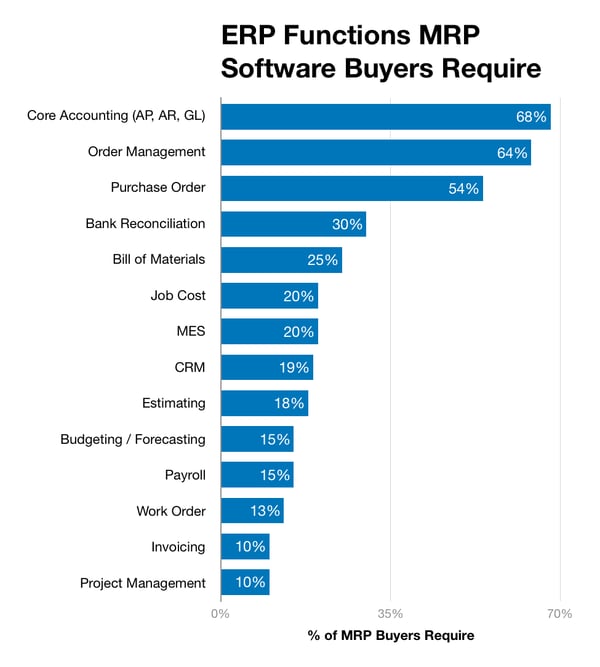

Report Mrp Software Buyer Trends

Erp Mrp Mes What Manufacturing Scheduling Software A Small Company Needs For Production Scheduling And Control

Mrp Mrp Ii E Erp Youtube

Erp Vs Mrp What Are The Key Differences

Mrp Vs Mrp Ii What S The Difference

The Difference Between Mrp And Mps Archerpoint

Difference Between Mrp And Erp Geeksforgeeks

.png)

Workclout What S The Difference Between Erp Mrp Sap And Aps

Step By Step Process For Storage Location Mrp In S4 Hana Migration Sap Blogs

Enterprise Resource Planning Erp Mrp Systems Mrpeasy

A Brief History Of Erp Since 1960 And The Future Of Erp

Supply Chain Management And Mrp Erp

Mrp Vs Erp Which Solution Is Right For You Mrpeasy

Dynamic 3i Free Edition Erp Mrp V3 2 Screenshot Freeware Files Com

B E L Systems Limited

A Breakdown Of Common Acronyms Mrp Vs Mrp Ii Vs Erp

Www Omniaccounts Co Za Articles History Of Enterprise Resource Planning

Mrp Versus Erp Manufacturing System

Mrp Vs Production Control Vs Erp A Comparison Fitfactory

Mrp Vs Erp Key Difference Between Erp And Mrp Systems

Mrp Vs Erp Understanding The Differences And Benefits

Chapter 5 Mrp Erp Operations Management Enterprise Resource Planning

Mrp And Erp Systems Passport Software Inc

What Is The Difference Between An Mrp System And An Erp

Report Mrp Software Buyer Trends

Erp In Operations Management Significance And Key Components

What Is The Difference Between Erp And Mrp Vienna Advantage

Mauly Chandra Erp Systems Are Result Of Continuous Evolution It Started With Inventorycontrol System To Mrp And Then To Mrp Ii And So On And Today Erp2 0 Looks Like This

Mrp Vs Erp Key Difference Between Erp And Mrp Systems

Material Requirements Planning And Material Resource Planning Software

Http Www Saimgs Com Imglib Lightbox Download Assets Erp V Mrp Pdf

Erp Mrp Service In Anna Maria Complex Kochi Id